Company Profile

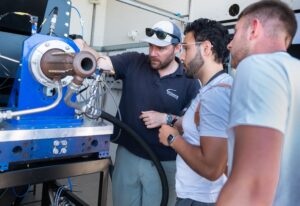

Airborne Engineering Limited (AEL) provides design and test services to the aerospace industry and academia, with a focus on chemical propulsion research. We operate two state of the art propulsion test facilities, supporting rocket engines using a variety of liquid and gaseous propellants. We have designed bespoke test rigs and control systems, tested injector and nozzle geometries, and evaluated the performance of new propellants and materials. Our customers rely on us to deliver successful cutting edge test programmes on time and on budget.

Our J1 test bay can accommodate a wide range of engines and propellants, including as standard: liquid oxygen, liquid methane, gaseous methane, liquid nitrogen, nitrous oxide, alcohols and hydrocarbons (e.g. kerosene). Our J2 test bay has gaseous feed systems for air breathing rocket engine research, flow testing or fundamental combustion research. This facility includes a high flow rate air and hydrogen supply, water cooling, water spray sound suppression, and automatic metering valves on all propellant lines.

AEL can also offer pressure testing and heat exchanger testing. We also develop custom ground support equipment (electrical and propellant loading), fluid handling components or rocket engines to meet specific customer needs.

Services Offered

Propulsion test and evaluation

At our Westcott facility, we have a well-equipped on site mechanical workshop and instrumentation lab and two rocket engine test bays covering a variety of propellants and thrust ratings up to 40kN. We are able to test at higher thrust levels elsewhere on the Westcott site if required. Each test bay has extensive data acquisition and control support, which can be extended for specific experimental requirements as necessary. Raw data and automated reports are available immediately after a firing is complete, allowing rapid turnaround and efficient test schedules.

The J1 test bay can accommodate a wide range of engines and propellants, including as standard: liquid oxygen, liquid methane, gaseous methane, liquid nitrogen, nitrous oxide, alcohols and hydrocarbons (e.g. kerosene). Its modular structure allows us to quickly reconfigure the test bay to support different customer requirements, including hybrid engines and speciality propellants.

Our J2 test bay has a purpose-built high-pressure air flow system for air breathing rocket engine research. This facility includes a high flow rate air and hydrogen supply, water cooling, water spray sound suppression, and automatic metering valves on all propellant lines. Our custom designed metering valves are digitally controlled and can either follow a specific mass flow profile to better than 1% accuracy or can be set to allow closed loop control of engine operating conditions such as chamber pressure. While J2 is predominantly used for air breathing rocket work and gaseous propellants, it can also be configured for other types of rocket engine, hot gas generation for heat exchanger research, and hypersonic wind tunnel testing.

Whilst our facilities are usually used for testing rocket engines or subsystems, they may also be used for other applications such as flow testing, pressure testing and heat exchanger testing (either with hot gas or gas cooled in a liquid nitrogen bath).

Custom hardware design

AEL regularly design and manufacture custom equipment for the aerospace industry, including:

- Rocket engines and their components (injectors, combustion chambers etc.) for a variety of customers, for custom applications or proof-of-concept demonstrators

- Ground support equipment (GSE) for propellant handling

- Pressure regulation panels for use in propellant labs

- Electrical ground support equipment (EGSE) for propulsion systems

- Data acquisition and control systems

- Custom valves for test rigs (high flow rate, throttle control etc.)

Skills and experience

Our staff have a wide range of engineering, scientific and business experience, having previously worked on projects including stratospheric balloon records, aerodynamic decelerator testing, radio frequency propagation studies, meteorological radar, general aviation and various rocket engine programmes. Our staff have over 100 years combined experience in rocket systems design and testing.